Jul 1 2005, 09:53 AM

Dennis,

Good questions. Actually I don't recall discussing these points,

so I'll do so now.

My top and back attachment methods have evolved to the point

where you see them now. I prefer installing the top using tentellones

because, even though it might take a little longer, it is inherently

more flexible, and it is easier to boot. I decided to space out

the tents the way I do now after seeing the interiors of a couple

of very nicely built guitars, and decided that I really liked

the look, and realized it would also take about half as long.

I don't think that spacing out the tents affects the structural

integrity of this joint at all, especially once the binding and

purfling have been glued into place.

I used to install kerfed linings for the back, but have switched

over to solid ones for my last few builds. Once again, I like

the cleaner look. Like many other builders, I use basswood for

the linings. Basswood, however, does not like to bend all that

well. It tends to wrinkle at the waist bend and it tends not

to want to hold its bent shape. So, to get around this, I cut

the lining strips about 0.100" (2.5mm) thick, and then bend

them, which elminates the chance of developing a wrinkle at the

waist bend. And then, I laminate two of the strips together,

using my mold for side bending, clamping them down on the mold.

This works well. When they come off the mold after the glue has

dried, they are quite rigid and there is essentially no spring

back. Thus they actually help to preserve the side shape. The

final thickness of about 0.200" some would say is too thick,

but I don't agree. Kerfed linings are also about this same thickness.

Hope that helps some.

Best, Michael

Jul 5 2005, 12:22 PM

Things have been kinda hectic around here lately. I was initially

hoping that I could have Stephen's 10-string finished in time

for the First International 10-String Guitar Festival being hosted

by Janet Marlow in Litchfield, CT. That isn't going to happen,

unfortunately, but at least one of my guitars will be there.

And it will be in some very heady company.

Today is the day for getting everything packed, and tying

up the loose ends. Tomorrow I'll be flying out of Houston for

Hartford, CT, where I will meet up with Stephen. We'll be sharing

a rental car for the 40-or-so mile drive into Litchfield.

It pretty much goes without saying that I'm looking forward

to this. This will be my first opportunity really to exhibit

my work in a more formalized setting.

I'll be back Sunday evening, and some time next week, I'll

be sure to post a full report.

Best, Michael

Jul 5 2005, 12:30 PM

Meanwhile, the work on number 9 has continued. I've made quite

a bit of progress since my last build update, so I think I'll

break it up into a couple or three smaller posts.

Tell you what, though, it's been really hot down here. How

hot? Well, not Phoenix hot, but hot enough!

Yeah, but it's a dry heat. Yeah, right. That's the the

temp being read by the outdoor sensor. See the time? That's in

the PM, btw. At midnight it's still often above 90F.

Inside the shop, with the little window unit A/C wheezing

away, it's a balmy 80 degrees

This helps some:

Easy does it though, or else my mitres will start getting um

-- approximate.

Best, Michael

Jul 5 2005, 12:37 PM

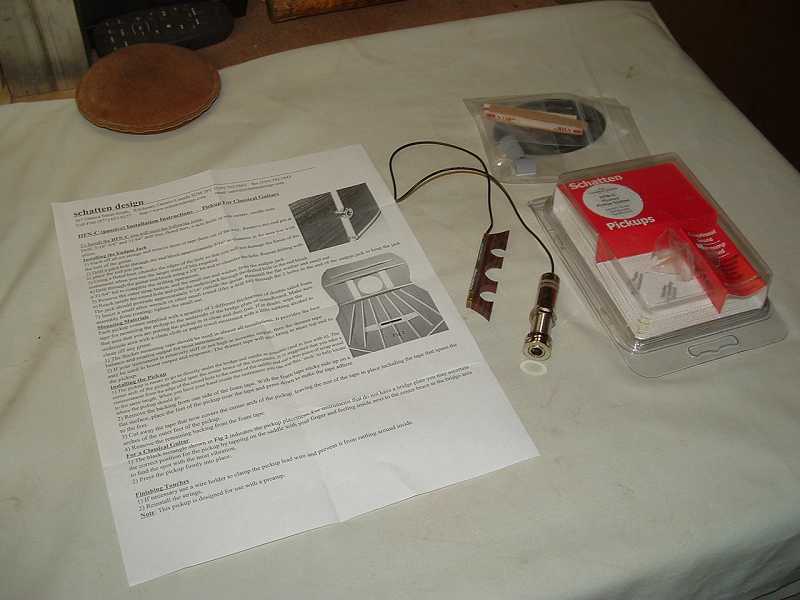

Stephen has decided he wants a pickup mounted in this guitar.

He chose a Schatten model. Here's a shot of what you get with

this one -- it's the passive model, which requires an external

pre-amp. Glad he elected to go with this style PU, cuz that way

I don't have to cut a big hole in the side.

Here's a close-up of the pickup and the jack. Yup, that's a piece

of EIR it's bonded to.

Call me anal, but I decided to go ahead and contour the pickup's

feet.

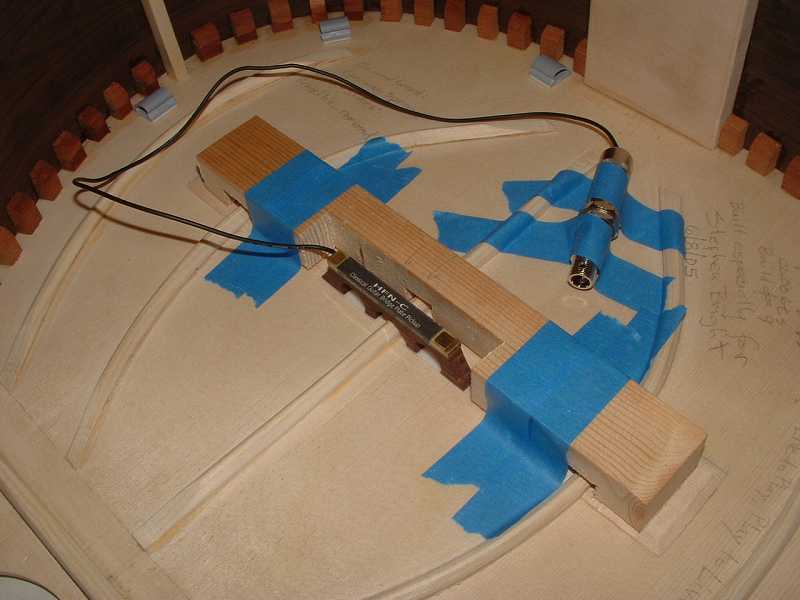

The pickup is fastened to the soundboard using a thin foam adhesive

strip. I located it exactly along the bridge saddle centerline.

Then, I decided to cut the bridge caul and tape it and the pickup's

jack in place before gluing down the back. It wasn't strictly

necessary to do it this way, but it makes for an easier installation,

I feel.

Then I inletted the sides and linings for the back braces, and

glued down the back

Next up, routing, binding and purfling.

Best, Michael

Jul 5 2005, 12:51 PM

I got to try out my new DeWalt laminate trimmer on this guitar.

Rather than use the standard base, which has sufficient adjustments

to make the various stair-step cuts I needed to make, I elected

to use instead the router bit set I bought from Tracy. I thought

the accuracy might be a little better.

Turns out there was still a fair amount of variability between

the binding channel and the outer edge of the purfling ledge

-- enough to where I had to improvise a solution.

The binding is EIR. I could have tried using offcuts from

the Brazilian sides, but they had already been thicknessed down

to such a point that I was afraid I'd burn through the binding

in places, when scraping everything down. So I decided on some

nice looking EIR instead. The binding installed easily.

To install the side purfling, I decided to try an approach

outlined by Rik Middleton in his book.

You'll note the small pieces of purfling glued in place along

the binding channel. They act as spacers to give the binding

the right amount of standoff. After everything has dried, I take

my 1mm graver, and chisel out the purfling pieces.

Then I take the purfling, soak it for a few minutes in water,

and push it into the channel. I use the butt end of an X-acto

knife to push it all the way in place. There were a few places

where the channel was a tad too narrow, and I used the X-acto

knife to trim just enough away at these spots so the purfling

would fit.

After than, I mixed Titebond with water to make a "glue

soup." Not too thin. I spread the soup liberally over the

purfling and let it soak in for a few minutes -- the purfling

kinda acts like a sponge; it actually soaks in pretty quickly.

Then wiped away the excess and taped it down along spots where

it might not fit all that tightly.

Best, Michael

Jul 5 2005, 12:59 PM

Next came the top purfling. This is really wide stuff, and fragile

to boot.

Here's a shot of a soaking tray I made out of aluminim foil

with one piece of the top purfling in it. If you look closely,

you can see where it separated when I tried to bend it on the

mold.

The purfling for the top originally had black strips on the outside,

but I ended up having to remove one of them -- the strip that

would ordinarily lay against the binding -- to reduce the width.

Even though I measured more than twice before I cut once, the

router bit cut the channel a little narrower than I needed, so

in order to get it to fit, I had to remove that strip. No biggie.

Here's the way it looks after being installed.

I used the same "glue soup" method for this purfling

as well. It really does not like to bend. Because it is so wide,

there is a significant difference in the length of the arc of

the inside strips of wood compared to the outside strips once

you start trying to bend it. And if you try to force it, the

fragile interior mosaic begins to shear and separate. The solution

was to cut the purfling after a certain length of bend, and to

butt up a new piece, trying to match the pattern as closely as

possible.

I still have a little bit left of the top's purfling to do,

but I dunno if I'll have the time to do it before I leave for

the Festival. The back's purfling is definitely gonna have to

wait till I get back.

That's it for now.

Best, Michael

Jul 5 2005, 01:16 PM

Michael,

You really have the binding/purfling process down pretty well.

I admire your willingness to jump in and do it.

With time the EIRW binding will color itself to a more brown

color tone and should blend right in. I see I need to really

study the R. Middleton space block description some more. Seems

to work quite well for you.

Good luck at the festival. Hopefully all will welcome another

10 string builder. If not it's their loss. Have fun.

Steve

Jul 5 2005, 03:24 PM

Thanks for the nice words, Steve. The old saying is true, though

-- you know, the one that goes something like, the more experienced

you get the better you are at hiding your mistakes? In this case,

it isn't really mistakes, just slight inaccuracies that lead

to gaps and tight spots. I've just gotten better at hiding them,

is all, but I tell you what -- the biggest help in this regard

has been moving to the use of a heating blanket and mold, instead

of trying to bend this stuff by hand over a pipe. Not only is

it much more accurate, it's way faster. A very good investment,

it was.

I haven't felt the need to do the space blocks the way Middleton

outlines in his book until now. And it was due to the fragile

nature of the purfling.

With my other builds, what I've done, with good results, has

been to glue the purfling to the bottom edge of teh binding strips

before bending them, and then bend. If I bend them dry, things

usually work out okay, although I have had an occasional separation

between the binding and purfling due to the heat making the Titebond

maleable. I find, though, that if I clamp it down when it's still

warm, I can usually correct this.

Right now, I think the EIR and Brazilian are already very

close in color. This is a very dark set of Brazilian, so I think

using EIR as binding will be something almost nobody will notice.

The 10-string community is a small one. But the number of

builders who build 10-strings is much smaller. So, my experience

has been one of being greeted with enthusiasm over the news that

there is another builder of 10-strings out there.

In fact, when Janet Marlow learned I was coming, she asked

if I would give a talk on building a 10-string to the Festival

attendees. Of course, I was more than happy to say yes.

There will be at least one player there who has a fair amount

of experience in building 10-strings -- Perf De Castro, who is

also a member here. If I recall correctly, Perf helped a luthier

with the construction of his first 10-string, and then more recently

he did a major overhaul to that guitar, replacing the fingerboard,

which is no small feat, so he's a luthier, as far as I'm concerned.

Anyway, it will be a lot of fun getting to compare notes with

him as well.

I'm planning to take not only my camera, but calipers and

a tape measure so I can sample various metrics of the guitars

at the festival. I feel not unlike a paleontologist being turned

loose on a virgin bonebed.

Best, Michael

Jul 14 2005, 07:15 PM

Okay, now that things have begun to return to normal after the

10-string Festival, I've had a chance to turn my attention back

to build #9. The night before I left for Litchfield, I managed

to glue down the last of the purfling.

Scraping down this delicate purfling was interesting. I got

what I call "blowout" along the top and "burn

through" in a couple of spots on the back. To me, "blowout"

is where hunks of purfling fall out when scraping, and "burn

through" is when the purfling wasn't completely seated in

its channel, resulting in total removal of the purfling or parts

of it in spots while scraping.

I suspect the reason why the hunks of purfling fell out was

because of the Titebond soup I used to glue it down. Even though

it soaked well into the mosaic, the bond was not sufficient in

a few places. So, I went back over all the purfling with

thin CA.

Some spots were bigger than others.

Now I wish I had a good explanation as to why I decided to saturate

the purfling with CA before I replaced the blown out areas.

When I think of it, I'll add it in a future post.

So, I had to go back into the channel and chisel out the dried

CA in prep for the new purfling.

The burn through on the back was less obvious. Just a couple

of short sections of the white inner purfling line was lost,

which necessitated trimming off a bit of white, deepening the

cut for the white line, and gluing it in place. Using CA this

time, of course.

Still, all in all, the guitar is coming along pretty nicely.

Here are a few shots after I finished scraping down the binding

and purfling and repairing the blow outs and burn throughs.

The Brazilian rw has several small wormholes that I've begun

to fill. I discovered that my thick CA has gone off, and no longer

hardens. It made a lovely mess, so I had to scrape and sand it

off, and fill with some fresh medium CA.

Tomorrow, more sanding and probably a bit more filling. Then

I'll get to install the fingerboard and begin contouring the

neck.

Best, Michael

Jul 26 2005, 04:33 PM

Welp, more interruptions, including a shoulder injury I sustained

picking up a recalcitrant 65 lb. canine, set me back a bit on

this build. I've been making tolerably good progress for the

past several days, though.

Here's the latest:

After getting all the purfling squared away, I installed the

fingerboard, and then contoured it for bass string relief. As

I mentioned earlier with the first 10-string build, a lot of

relief needs to be planed into the fingerboard because those

big, floppy bass strings move around a lot. After doing the contour,

I sanded down the fb with a homemade sanding block I use, made

out of a 2"x 3" x10" piece of aluminum, to which

I have glued down a piece of 80 grit sandpaper. Such a stout

block makes it a lot easier to sand out any irregularities to

the contour.

However, afterward, because of the depth of the contour, the

fret slots are no longer deep enough.

So, I had to recut the slots (I taped up the upper bout area

first, though), and then checked them with a piece of fret wire

with the tang barbs removed that I use as a depth checking tool.

Installing, leveling, and recrowning the frets was next. I don't

mind admitting that recrowning frets is not one of my favorite

lutherie-related activites. But it is an absolutely essential

one. The following shot was taken before I'd masked off the entire

fingerboard.

After installing the frets, it's time to tidy things up a bit

around the soundhole. I decided not to install that tiny vestige

of the 19th fret above the soundhole. It never gets used on a

10-string, so I just filled it's little slot with CA and ebony

dust. Filled gaps around a few of the other frets too. Looks

messy now, but wait a while . . .

Somewhere, when all this was going on, I installed the heel cap.

I think this will be the last heel cap I install for a while.

Next build, I'm gonna try leaving an extension of the back in

place to act as a cap, and lay purfling/binding around it, instead

of installing a separate cap. I noted at the Festival that both

Nunez and Bernabe did this.

Once the fingerboard was installed and all, I finally turned

my attention to contouring the neck. I start out with spokeshaves,

graduate to rasps, then files, then sandpaper, and finally steel

wool. I'm still at the rasp stage in the following image.

But it doesn't take too long to get to this:

Still only about halfway done with the neck, though. I still

had a few hours of gentle contouring and sanding ahead of me.

I've been putting off drilling a hole in this guitar long

enough. Time to pull out the old bit brace and a 1/2" bit

and drill a hole for the pickup jack. Initially, I tried using

a Forstner bit. Way too slow, but it started a clean hole. A

bit brace is fast and usually cuts a very clean hole, as well.

A moderate close-up of the front of the guitar. The image is

a little dark, but I think you can see that the fills I made

at the end of the fingerboard came out pretty well.

The above photo was taken after a couple of wash coats of shellac

had been laid down. Here's a couple of shots of the rest of the

guitar after the wash coats of shellac.

Next, I'm gonna fill the pores. That should be fun.

I hope to have this guitar finished by the weekend. So far,

we're on track.

Best, Michael

Jul 26 2005, 04:42 PM

Michael,

Your details are coming out well.

That sure is one big neck though. Hard for me to believe the

size of the thing I had not seen your pictures.

The B Rosewood looks great with the mahogany.

Steve

FIRST

PAGE / PAGE 1 / PAGE

2 / PAGE 3 / PAGE

4 / PAGE 5 / PAGE

6 / PAGE 7 / PAGE 8

Home / Articles

/ Gallery / Accessories

/ Builders / Composers

/ Guitarists / Movies

/ Sheet Music / Free

PDFs / Recordings / Teachers

/ Radio / Join

/ Contact Us