|

May 28 2005, 11:36 PM

Hey Steve,

Haven't started with the Brazillian yet. I'm taking things rather

slow here. Trying to figure out all possible things that could

go wrong with build #8 before trying most any of it on build

#9.

I have found the Bolivian to be somewhat prone to splintering.

Especially the sap wood. One has to exact a bit of extra care

when working with Bolivian rosewood, or else it will chip and

splinter on you. However, I have found that it carves well with

sharp chisels.

Of course, the other caveat about Bolivian rosewood is that many

folks are extremely allergic to it. Same goes for cocobola

as far as that goes -- with some folks.

Regarding the bracing pattern, I still consider it to be experimental.

I like the concept of having an "open" upper bout for

classicals, but folks need to realize that the result will be

guitars that will inevitably sound somewhat differently from

"standard" classicals. So ultimately, the question

at hand will be whether an open design for the upper bout has

acoustic merit. The answer will be determined in large part by

preferences that are as old and varied as the nuances of classical

guitars themselves.

Best, Michael

May 29 2005, 01:55 AM

ramirez must not be traditional, or my eyes are bad, for the

10 string you used to start the thread, and every other one i'm

familiar with has the cl of the twelth fret tangential to the

curve of the body where the neck joins.

May 29 2005, 08:09 PM

Michael,

Remember, it is said there are two kinds of people, those who

are now alergic to these tropical woods and those who will be.

Use them while your are able.

Steve

May 31 2005, 10:48 AM

You know, Steve, I was thinking about that just yesterday. I

have a light rash on my left arm that suddenly appeared yesterday

-- pretty much gone now, though -- and the most likely culprit

is this guitar's Bolivian rw.

Time to dig out the good dust masks and long sleeve shirts. I'm

gluing down the binding and purfling today, so next step is scraping

and sanding. The binding is Bolivian also.

Best, Michael

Jun 2 2005, 11:18 AM

Welp, this got me to wondering because I knew I'd seen 10-strings

with the 12th fret at the body joint. So I searched around, including

at Stephen Bright's Yahoo site dedicated to 10-string guitars.

Dunno if you have to be a member to access the Photos section

there. Anyway, if you look there, you'll see what appears to

be both methods of joining the neck to the sides.

I sent an email to Stephen, who's commissioned me to build #9

for him, asking him about the 12th fret positions on his two

10-strings, one is a Ramirez, and the other is a Lucio Nunez.

The Ramirez's 12th fret is placed where it would be placed on

a 6 string, about 0.10" nutward of the neck to side joint.

However the Nunez's sides join the neck at the 12th fret.

The way I see it, the biggest difference from a player's perspective

between the two fret placing methods is that the soundhole will

take a bigger bite out of the 19th and higher frets with 10-strings

that have the 12th fret at the body joint -- unless the soundhole

has been similarly moved. But considering that the fingerboard

is wider and that the treble strings are displaced southward,

my measurements indicate that I should be able to wrap the fingerboard

on guitar 8 out to the 22nd fret. High E string only though,

by the looks of things.

This construction method positions the bridge rearward by the

same amount. I can see how this might affect the overall sound

somewhat, but I'm wagering that any effect will be minor.

Best, Michael

Jun 2 2005, 12:54 PM

Next step was to route #8 for binding and purfling and to install

it. With this guitar, I decided to go with non-contrasting binding,

so I trimmed a couple of strips from the sides and cut each into

binding pieces. I got six pieces out of this set of sides. Five

got used.

Purfling for the top was from some curly maple veneer I cut using

a pasta machine. I dyed the colored purfling using fabric dye.

Purfling for the sides and back is also curly maple, cut from

a board that I use just for purfling. I thickness the latter

with my drum sander down to 1mm (0.040") usually, sometimes

0.022". The trick to getting purfling this thin is to place

it on a very flat board and run it through using the board as

a support piece.

I started by doing a dry fit of the binding and purfling, making

sure everything is lining up right.

Then, partially following Rik Middleton's methods, I installed

the binding . . .

And then the purfling. Did this with both the top and the back.

Middleton glues his purfling and binding down with cyanoacrylate.

I don't care to do this. I use Titebond. To glue in the purfling,

I water the Titebond down til it's kinda soupy, install the purfling

and blot it liberally with the water-glue mixture as I go along.

Saw Grant use a technique similar to this with the rosette, I

believe it was, on his adjustable neck build, and I've kinda

been partial to it ever since.

Scraped and scraped and scraped . . .

And then sanded some and it was starting to look right.

At the bottom end, things fitted together as nicely as I could

have expected. Got some chip out on the butt splice though. Have

I mentioned yet that Bolivian rosewood is prone to chipping?

Especially the sapwood. There are several small areas on this

guitar that will need some attention before I begin to put a

finish on it.

Next I'll slot and install the fingerboard. Still got quite a

bit of sanding and contouring of the neck heel to do yet, too.

Best, Michael

Jun 2 2005, 02:17 PM

Michael,

I am enjoying your build pictures. You are making progress. Nice

job.

I went to Middleton's site and really enjoyed it. Do you think

I should buy his book? I guess I mean do you think there are

enough overlaps between his classic builds and my steel string

flat tops?

I think you will like using the KTM9. Boy, does it polish up

nicely. It also seems to cure harder that nitro or shellac. The

finger rest on my archtops show very little wear from my nails

or rough fingers.

Just think about that Bolivian RW made me itch though.

Steve

Jun 4 2005, 11:50 AM

Last month I bought a StewMac fretting jig. I wanted to use it

with the 10-strings although I knew it would be too narrow. Fortunately,

it comes apart, and I was able to insert a piece of aluminum

to widen the base. Forgot to take pictures until I was bolting

up the modified assembly.

Finally ordered the template for this rig. I should be cutting

number 8's frets next week.

In the meantime, I've been working on guitar 9. I've joined the

top set and back. Because the back set was already cut to approximate

shape, I had to improvise when it came to clamping it down. This

method worked pretty well.

The purfling scheme that Stephen selected is very wide. Because

of the width of the purfling, I used my binding/rabbetting bit

set to rabbet a ledge for the purfling to sit on, preserving

in the process a rosewood-to-rosewood joint. I didn't do this

with guitar 8, since the purfling was a single 1mm wide strip

of curly maple.

Bent guitar 9's sides yesterday, too. First time I've bent Brazilian.

It was cooperative, no unpleasant surprises.

Best, Michael

Jun 8 2005, 11:55 PM

The template for my Stewmac fretting jig finally arrived yesterday.

I put it into service today.

Using this system on a 10-string fingerboard is more involved

than with a 6-string, mostly because the jig's box is too wide

now for the template with the additional aluminum insert I installed.

The template would nortmally fit snuggly between the two sides

of the box, preventing the fingerboard from moving around. But

because of the extra width, I had to clamp it down for each cut.

I found that, once I got the jig tweaked and adjusted, that it

worked pretty well.

I made a new gluing caul for this step. My regular one isn't

wide enough.

Never can have too many clamps . . .

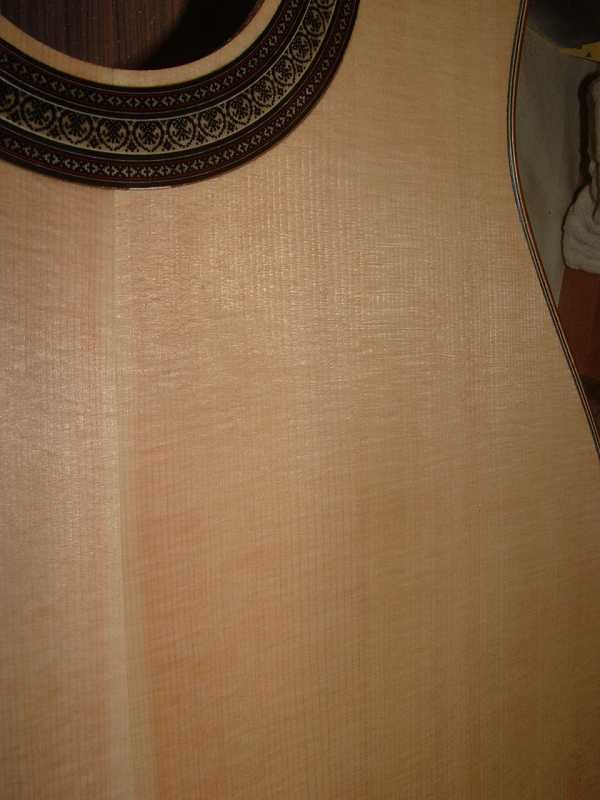

But before I did all this, I spent some time on the top. Sanded

it to 220, then put down a couple of light sealer coats of shellac.

This is a Kermodie spruce top. It has some very nice silk that

has a bit of figure to it. This photo doesn't really do it justice.

Tomorrow I begin to finish up on the neck.

Best, Michael

Jun 9 2005, 01:08 PM

Michael,

You are getting really good with your binding. This one looks

super. That spruce does look nice. It will sound good too.

Steve

Jun 9 2005, 01:57 PM

I agree with Steve-Great job matching the B&S's too-Ive noticed

that even the best of the best sometimes don't seem to take the

match into consideration whilst joining-

-question-Tuners?10 strings?

Jun 9 2005, 09:22 PM

Thanks guys.

WB, I'll be using different tuners for each guitar. Stephen has

supplied a set of Alessi's (he's also a US distributer of them),

and I plan to cut a pair of Hauser-style Schallers.

Here's Stephen's five-on-a-side tuners:

And here are the two sets of Schallers. I've dismantled both

right side sets already.

I'll document how I cut the Schallers in a future post.

So, why cut when I can order a set of five-on-a-side tuners?

Well, Jose Ramirez, the originator of the modern 10-string, cut

tuners for years. Fusteros -- not cheapies. So, cutting tuners

works just fine. Nowadays you can find a few makers of tuners

who make them for 10-strings. None of them are in the same economy

class as the Schallers, though. And for me right now, the Schallers

fit my budget.

Best, Michael

NEXT PAGE / PAGE 1 / PAGE

2 / PAGE 3 / PAGE 4 / PAGE

5 / PAGE 6 / PAGE

7 / PAGE 8

Home / Articles

/ Gallery / Accessories

/ Builders / Composers

/ Guitarists / Movies

/ Sheet Music / Free

PDFs / Recordings / Teachers

/ Radio / Join

/ Contact Us

|