|

Apr 24 2005, 08:30 PM

Hey Steve,

Regarding the headplate, Stephen told me that he has some Brazilian

scrap that he's gonna look through and see if any of it is useable.

Hopefully, he'll have some. If not, I can order an oversize ebony

plate from LMI. Stephen doesn't mind going with an ebony headplate.

The other alternative will be to go scrounge for something at

one of the hardwood stores here. I'm thinking that the Brw veneer

you have will be too thin for a headplate, right? I'd need something

at least 0.080" thick. Thanks for the offer, though.

Best, Michael

Apr 24 2005, 08:49 PM

Michael,

Just wanted to give you some options. Didn't want your first

commission to fizzel for want to BRW.

BTW - I have used normal veneer for head plates many times. Usually

I use some contrasting color veneer under the top show piece

but I haven't ever had any issues.

Steve

May 27 2005, 10:38 PM

Okay, okay. Been meaning to post an update. Building a 10-string

classical is more different that it appears on the surface. Not

really harder, but a bit trickier in a couple of steps. WB, yup,

we did get the headplate details sorted out. Dean, as a matter

of fact, I did buy a brisket for the weekend. It goes on the

fire tomorrow morning. Y'all want, I'll start a thread about

BBQing over in the WoodShop. Unless somebody beats me to it,

of course.

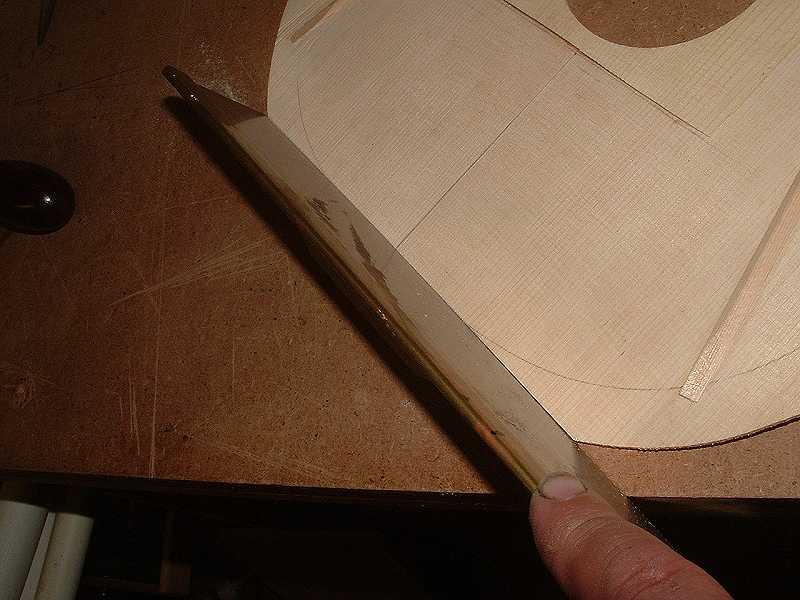

OK, well on guitar 8, I was able to use offcuts from the back

wood, bookmatch them and wind up with enough material for even

this oversize headstock. For appying the glue to the headstock

veneers and the headplate, I bought one of these cute little

things at my local hardware store:

Had to add a little water to the glue, though. I clamped and

reclamped this setup a few times, before I was satisfied the

headplate wasn't gonna slide around.

Cut to approximate shape, and marked out for tuner holes and

slots.

I keep threatening to build me a jig so I don't have to cut the

slots by hand anymore. Course if I would have, it wouldn't

have worked for this guitar anyway

So by this point the top was ready to be fitted to the neck.

Had to cut the top at the 12th fret position, which is where

it mates up with the top of the neck heelblock. Exactly perpendicular

to the guitar centerline. The 12th fret line is closer to the

soundhole than it is on a 6-string. About 0.100" closer.

I like to sharply peak my back braces. I dunno if I'm saving

any weight, because they're taller than what one typically sees,

but I think a sharp peak is stiffer than a rounded one. Given

that a classical's back provides most of the instrument's structural

rigidity, and given that it will be having to deal with approximately

66% more string tension, any increased back stiffness should

be a good thing.

Glued the top down to the neck and sides, then glued down the

flying tone bars, side braces, and linings.

It was at this point that I discovered another important difference

between 10-string and 6-string construction. Because of the extra

neck width, the neck attaches to the body at a different location

on the body. Since this location is slightly lower (toward the

soundhole), the angle at which the side intersects the neck is

greater. I didn't tumble to this until it was too late. Result?

I've got gaps between the upper portion of the neck heel and

the sides. Solution? Hell, I'll probably just shove some mahogany

shims up in the cracks and chisel them even. Yeah, it'll be end

grain there, but oh well! Oh, you meant, the correct solution!

Well, it occurs to me that if I just increase the angle that

I cut the neck slots, that this might work well for the upper

half of the neck heel. But then that increased angle might make

the sides look like they're forming a point at the base of the

neck heel. So it seems obvious that the real solution will be

to cut the side slots at the exact decreasing radius curve that

the sides form during that same period of travel.

Hooboy. Reckon I'll install a new bandsaw blade before I cut

guitar 9's slots.

I picked up a handy tip from Lucio Nunez when it comes to basswood

linings. Dunno about you, but I have problems with basswood creasing

and wrinkling at the waist's bend. Even if I'm using a heating

blanket. Guess Lucio has too. So, what he does is cut his basswood

into strips that are half as wide. So, instead of 1/4" thick,

they'd be 1/8", instead of 3/16", they'd be 3/32",

whatever.

These thinner strips bend ok. So, he bends up a bunch of the

thin ones, then laminates pairs together. What I did was, after

laminating the strips together, I set them on the mold with bending

blanket and ran the blanket at 250 degrees for about 5 minutes.

This softened the glue and allowed the two pieces to "seat"

against each other. Worked well.

Guess I should have taken pictures. The result, though was a

set of nice, smoothly bent linings with tight glue lines. And

no wrinkles!

Next, I notched the back and linings for the back's braces. Took

some tweaking before everything lined up right. Then I spent

some time with the guitar on the sanding board, insuring that

everything was even and ready for the back. The back glued down

without a hitch.

Today I routed and inleted both the top and back for binding

and purfling, bent some binding, cut and sanded down some purfling.

Tomorrow, I plan to install it.

Best, Michael

May 27 2005, 11:48 PM

Nice work Michael...I can see you have been focused and are making

some headway. A challenging project- pushing you alittle bit.

That's good in the long run. Nice clean work and I enjoy seeing

it again.

I thought of you this past weekend. A friend stopped in for a

short visit and showed me his new classical guitar. It had small

holes in the upper bouts to project bass response in larger auditorium

settings. He said even harmonics in large auditoriums sounded

like regular notes, from the audience. Maybe old hat- but new

to me. I took a few pics. Robert Ruck built the guitar and I

can send pics if interested.

Dean

May 28 2005, 08:39 AM

So Michael

You are still with us. I have been checking this thread every

once in a while to see what you have been up to. Have you decided

on finish yet...french polish or KTM?

Nice work....today we are doing a nice tip roast on the rotisary

on the bbq. It's been marinating all night in home made marinade

and a whole bunch o garlic cloves shoved into little wholes all

around the roast....Ya I know it's not a brisket, but it is a

big chunk of Alberta Beef Maybe we'll all be "mad"

when we're done eating

David

May 28 2005, 09:48 AM

I use sewing pins to keep things like this from moving during

clamp up. You can locate them in a section that will be cut away

later or cut them short to create a locating pin that stays buried

inside the piece. They will drive easily into material such as

mahogany, but you may need to go to a model shop and buy a set

of micro drill bits to drill a hole that small in harder wood.

This technique has made my fret board glue ups a breeze. I radius,

slot and bind my fretboards before glueing to the neck. To make

sure they don't move when clamping I locate a pin in the first

fret slot and in the 13th (14 fret steel strings, 12 fretters

make the adjustment ). I did have a problem once where the pin

stayed behind when I tried to pull it out. I wound up bending

it back and forth with a feeler guage until it broke off. There

was still a small bit of it left in the bottom of the fret slot

so I had to make a notch in the tang of the fret so it would

seat properly.

Greg N

May 28 2005,

10:29 AM

Hey Guys --

Just finished gluing in the buttsplice. Time to let glue dry

and check messages.

Dean, Robert Ruck is (was?) a legendary classical builder. I'm

sure your friend owns a superb instrument. Nowadays, quite a

few classical luthiers are installing various shaped holes into

the sides. Check out the opening photo at Randy Reynold's site.

I'll probably try porting a guitar one of these days. Heh. I

could use guitar #1 as a testbed, and port it. Good sounding

guitar -- just kinda ugly to look at.

David, I plan to get some KTM-9 and brush it on. I like french

polish a lot, but it is also a lot of work.

Ah, BBQ! Tip roast is good. Back in California, if we were barbequing

beef, we mostly barbequed tri-tip roast, which is probably the

most popular cut for barbequing there. Brisket wasn't very common.

Sounds like yours will be a good 'un.

Me, I'll just be using our regular brisket rub, and smoke the

meat over a low fire for probably 10 hours or so.

Greg, I use locating pins as well, but so far not for the headstock.

Prolly will some day when I get organized For now, I just use

them to locate the fingerboard.

WB -- 1581, eh? Now you got me wondering where Lucio got it from

. . .

Best, Michael

May 28 2005, 10:33 AM

One difference between 10-string and 6-string construction

that I realized right off the bat when laying out the dimensions

on this top is that because of the extra width of the neck, the

12th fret is moved bridgeward about 0.1":

i am puzzled by this statement, and fail to see your logic. could

you explain?

an outstanding photo essay by the way.

May 28 2005, 11:03 AM

I probably could have explained it better. Here's the long version.

When I began drawing up plans for this build, I realized that

modern 10-string builders have to make a compromise between structure,

aesthetics, and quite probably, sound.

What you find is that the point at which the 12th fret is located

is determined by a combination of fingerboard width and curvature

of the upper bout.

Let's say, for discussion's sake, that the width at the 12th

fret is decided to be a typical 2-7/16" or 62mm. Picturing

the rounded upper bout now, one can see that a 2-7/16" long

12th fret line will intersect the top by a shallow amount. Obviously,

the rounder the bout is, the further toward the soundhole the

12th fret line will have to be located before the top perimeter

is intersected by the 2-7/16" wide 12th fret line.

Now, let's take a look at a 10-string's 12th fret line. The 10-string

fingerboard is 100mm (3.94") wide at the 12th fret. This

approximately 1.5" of extra width means that the 12th fret

will have to be positioned closer to the soundhole before the

100mm wide line intersects the top's perimeter. The 100mm wide

12th fret line is positioned lower simply because it reaches

farther.

A bridgeward displacement of the 12th fret of course also means

that the bridge itself must be moved back by an equivalent amount.

Not a problem as long as the top is planned out from the beginning

with an awareness of the atypical location of the 12th fret.

The other issue is soundhole placement. Since one is moving the

12th fret bridgeward a tenth of an inch, what about the soundhole?

Shouldn't it be moved too? I don't happen to know how other 10-string

builders handle the sound hole issue. Me, I decided to leave

it alone. Mostly because I think moving the soundhole even 0.1"

is noticeable, from an aesthetic sense. I suspect that changing

its position probably would have some effect on sound as well.

Perhaps as much as changing the bridge location.

Best, Michael

May 28 2005, 01:07 PM

Michael,

Glad to see you have taken some pictures as you progress.

Also glad to have you participate. I was afraid we had upset

you - then I said to myself - naaaa we didn't even come close.

I will be interested in your assessment of those flying tone

bars. I like the idea of the continuous brace running from the

bridge area to the top of the upper bout. Makes good sense to

me, even for a six string classic.

How have you found working with Brazillion rosewood?

Steve

May 28 2005, 01:35 PM

michael

i see what you are doing but not a reason for it. it is just

that in my experience with classical, acoustic, bouzoukis and

citterns, whatever, the 12th, 13th, 14th or 15th, or whatever,

fret slot is normally positioned such that its cl is tangential

to the top of the body, rather than forming a chord across the

arc of the top of the body. am i correct in taking it that it

is just for aesthetic reasons you prefer the latter?

May 28 2005, 08:57 PM

Michael,

To me, worry about this small a measurement is splitting hairs.

There are so many other factors involved in tone quality/sound

that I find it hard to get excited about where the body happens

to join the neck. So long as you use the fingerboard to locate

the saddle, and the bridge itself centers pretty well on the

soundboard bracing layout, you shoud be a "no worry mate"

status. [My appologies to those from down-under who might read

this.]

As for the cosmetics of it all, that is pretty much up to you.

There aren't a lot of these things around for critics to compare

to. You are the trail blazer - at least in this neck of the woods.

If your customer is worried about it - well - that's another

story. Then if you have something diferent you have a sales job

to set him straight.

Steve

May 28 2005, 11:27 PM

Not aesthetics really as much as tradition. In classical construction,

it is a matter of tradition that the 12th fret is placed at the

point where a chord is formed by the width of the fingerboard

at the 12th fret intersecting with the curvature of the upper

bout.

Best,

Michael

NEXT PAGE / PAGE 1 / PAGE 2 / PAGE

3 / PAGE 4 / PAGE

5 / PAGE 6 / PAGE

7 / PAGE 8

Home / Articles

/ Gallery / Accessories

/ Builders / Composers

/ Guitarists / Movies

/ Sheet Music / Free

PDFs / Recordings / Teachers

/ Radio / Join

/ Contact Us

|