|

Jun 15 2005, 01:50 PM

Yeah, I have Middleton's book, and I have reviewed his purfling

installation techniques. In fact, I have tried out his method

of installing the binding, then the purfling on my last two guitars,

and this worked out quite well. But this purfling is a different

matter altogether. The iron is not gonna do any good -- not if

my heating blanked and a caul matched to my mold didn't. I'm

still thinking the easiest way to go will be to remove material

from the inside radii.

Best, Michael

Jun 15 2005, 02:31 PM

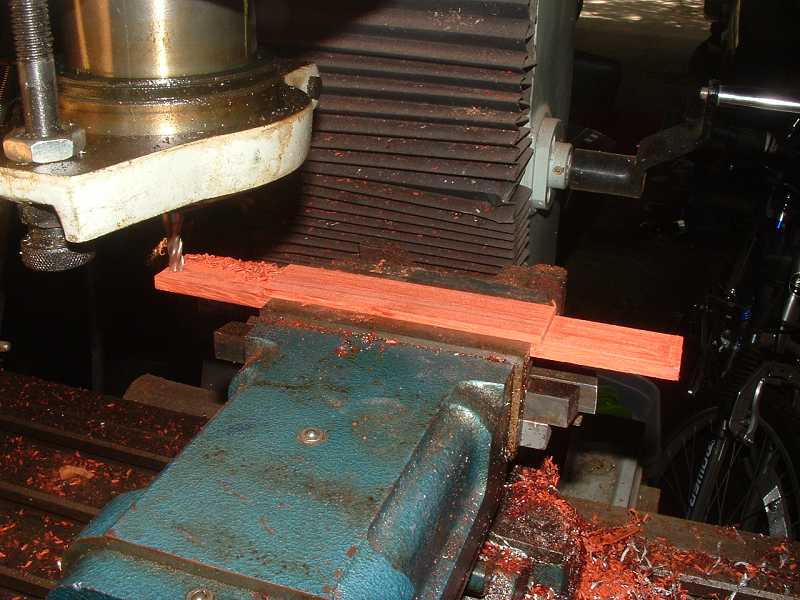

Yesterday, I began working on the bridge. I use my mill to cut

the blank down to its rough outer dimensions, and to cut the

slots. That's a 3/32" bit I'm using in the second picture

to cut the saddle slot and the slot between the tie block and

the saddle block.

Bridge dimensions for 10-string classicals are a matter of builder

preference, it appears. I have seen a few 10-strings with bridges

that are not really any bigger than 6-string bridges. The wings

are just shorter and stubbier. I think the concern among the

builders, such as Hippner, who prefer the shorter bridges, is

that a long bridge may affect the ability of the soundboard to

move freely.

Hey, makes sense to me. But reality doesn't seem to support this

position. The Ramirez bridge, which is the one I used as a basic

template, is 1.5" longer than a standard 6-string bridge,

and that longer bridge sure doesn't seem to have an effect on

the Ramirez 10-string guitars. The one I owned for many years

was quite loud and reasonably well balanced.

Me, I prefer the longer bridge because it is acting as a cross

brace and adds cross-grain stiffness to the top. But I want to

avoid the extra weight, if at all possible.

So far, I have built three classicals using padauk as a bridge

material. I like it because it is reasonably hard, but very light.

A typical classical bridge made from EIR usually weighs between

26 and 30 grams. This padauk bridge that I just finished for

guitar 8, even though it is 1.5" longer than a typical classical

bridge, tips the scales at 16.8 grams.

Almost twice as light.

The EIR bridge in the photo weighs 28 grams. The padauk one below

it, not even 17.

For the tie block inlay, I just went with ebony. I like the contrast

between ebony and padauk, anyway.

Welp, the neck still needs a little more attention before I begin

to apply finish for real. I should be able to complete that today.

With a little luck, I can start on the finish tomorrow.

Best, Michael

Jun 15 2005, 10:01 PM

Michael,

I'm enjoying watching this build (soon to be "these builds".)

How well did your countour sanding work out? Was it just a few

thousandths here and there?

I know so little about classical guitar construction (though

I do have Sloan and Cumpiano/Natelson's books) that I was unaware

that anyone used curved braces on classicals. I thought just

about everyone making classicals used "classic" construction.

(Other than the double-top stuff, and the radial brace guy, and...)

The Padauk looks sharp with the Ebony accents on the tie block.

I'm quite surprised that there is that great a difference in

density to EIR, I would not have guessed it.

Gonna need an MP3 when these babies are done, and settled in!

Dennis

Jun 16 2005, 11:21 AM

Hey Dennis,

When you're referring to contour sanding, I take it you're referring

to guitar 9's top?

As for the results of shimming my workboard to contour the top,

I think it worked out pretty well. I have a dial-indicator setup

that I used to check thicknesses after contouring the top, and

they were coming out reasonably close to target thicknesses.

As far as I know, Contreras senior was pretty much the only classical

builder of note who used curved fan braces. You know, Grant bends

his braces for the pattern he uses with his steel-string builds.

I still wonder, though, just how much a classical's sound is

dependent upon its bracing design. Of all the great classical

builders, there are almost as many different bracing patterns,

yet the sound quality differences between the guitars these guys

make or have made are not as great, IMO, as the differences in

the bracing patterns. Not nearly as great.

Best, Michael

Jun 16 2005, 08:49 PM

Michael,

Yes, the contour sanding I was talking about was your innovative

approach to sanding the top.

Your conclusions on variations in top bracing pattern snot having

a remarkable result in sound/tone could be somewhat liberating.

Now maybe you'll feel even more confident to experiment on other

classicals.

Dennis

Jun 16 2005, 09:52 PM

Hehe, Dennis -- truer words haven't been spoken -- for quite

a while, at least. If you investigate my earlier builds here,

you'll note that I'm not a slave to tradition. I do, in fact,

find this large "sweet spot" if you will, to be rather

inviting, when it comes to developing bracing patterns.

I'm actually quite happy with the one that I've installed in

guitar 8. This same pattern is in my 6th build. One of that guitar's

most pleasing characteristics is the sustain that it produces.

Its balance is great and its volume is comparable to that of

more traditionally braced guitars. But the sustain is remarkable.

I'm hopeful that build 8, which uses the same bracing pattern,

will show these same properties. That would be fantastic.

Best, Michael

Jun 17 2005, 06:48 AM

Yes, I have read your earlier builds, (especially your Zen),

and know that you do not fear innovation. I suppose there's just

a chunk of the classical guitar buying public that will always

want tradition, and for them, the more deviation from tradition

they can see from the outside, the lower the chance they would

buy it. But even for that group of buyers, innovations that are

hidden from view, like the bracing, are probably not deterrents.

Of course, whatever you build for yourself, well, the sky's the

limit on innovation. I'm not expecting you to install a whammy

bar or LED's in the fingerboard of a classical, but hope you

keep on with the spirit of the Zen. For example, I could see

you trying a radially braced classical, where the braces are

scalloped and the distance to the peaks follow the Fibonacci

sequence.

Now that I think of it, that classical with a whammy bar sounds

like a great idea!

Dennis

p.s. Sorry to veer off the 10 string road. These builds are plenty

interesting!

Jun 17 2005, 08:12 AM

Hah, My brother has been playing for 40 years and the inside

of a guitar to him amounts to nothing more than a hard place

to get a pick out of.

I kinda like the idea of a classical with strings lit from within

by a complicated fiberoptic network, computer driven to respond

to the sound frequencies, each note having a different color.

Jun 17 2005, 10:42 AM

That's what I did with the steel string I built. Dunno if it

had much of an effect. I've got some other Fibonacci-based patterns

in mind for classicals, however.

Best, Michael

Jun 18 2005, 11:00 PM

Welp, today I finally bit the bullet, sucked it up, and cut the

tuners. The Hauser style tuners by Schaller are the ones I selected

for guitar 8. As it turns out, for the cleanest installation,

there was only one possible way to cut the tuners. My measurements

told me that everything should fit up correctly after

being cut. But the real world has a way of intruding. The way

things wound up, I was left with about a 1/32" gap between

the two pieces. I don't consider this excessive, and I still

consider the way I cut them to be the most secure method of installing

them.

Here's a shot of the tuners still mostly dismantled, after I

cut them on my milling machine.

And after I've assembled them. Notice the two "leftover"

tuners. Dunno what I'll do with them. They only have one screw

hole each.

Mounted onto the guitar:

Here's a close-up of the joint, showing the gap I'm talking about.

Now, I could close the gap next time I build a 10-string by closing

the distances between strings 2 and 3 and 8 and 9 by 1/32".

But then, only cut Hauser-style Schaller tuners would fit the

guitar. I'd rather have the slight gap, just in case one might

wish to change out the tuners to a nicer quality set at some

later date.

Jun 18 2005, 11:21 PM

Got a little bit of work done on guitar 9 also. I used my bandsaw

to cut the neck heel's toe and tongue to approximate shape, then

got out the mallet and chisel to hog off some big chunks.

Next, I could have used rasps to bring the heel into the desired

contour, but I didn't feel like messing with them this time,

so I dug out the Big Blue Bit. Chucked it up in my Dremel Advantage,

and got busy.

These bits -- the ones that have the thousands of sharp teeth

-- are super aggressive on wood, and make a ton of dust. Because

of this, whenever I'm working on wood with one of these bits,

I'm doing it outside. Speaking of which, it was 98F outside today.

Hot and sweaty and dusty. Fortunately, it was less than 10 minutes

that I had to spend out in the heat because of the super aggressive

nature of that bit. But still . . .

Back inside my air-conditioned shop, I used a 4-in-hand to rough

the heel into an approximate final contour. Glad I have about

0.2" of extra heel length to deal with. You can see at the

bottom surface of the heel where the bit wiped across it, leaving

a nice divot in the process.

I've roughed out the neck heel enough now where I can turn my

attention to other matters. Next is to glue down the headstock

veneers and headplate, then cut out the headstock, tuner holes

and slots.

Best, Michael

_______

Jun 19 2005, 09:53 AM

M-I can see where the sides are going to go into the block, when

you get to this point could you post how you get them to butt

the outside of the block(heel) so they look nice and tight?

TIA, WB

PS Nice job on those tuners by the way

_______

Jun 19 2005, 12:54 PM

Wilf,

That was a problem I ran into with Guitar 8 -- getting the sides

to butt up flush with the neck heel. Problem has to do with the

angle of the upper bout where a 10-string neck meets the sides.

It's a few degrees greater than where a 6-string neck and sides

meet. I failed to account for this, but in the ensuing residual

neck heel contouring, this gap has all but disappeared.

For number 9, however, I increased the side slot angle by a few

degrees to account for this. I am hopefull this will take care

of the "problem."

Now, as to how I actually clamp things down, here's a photo of

guitar 8 with the clamps in place:

Note the black grip-style clamp situated behind the big Jorgensen

clamp. I have the grip-style clamp applying pressure at the top

of the wedges (in this orientation) and the Jorgensen applying

pressure at the bottom. When the sides are inserted in place,

the wedges stand slightly proud, since the sides are thicker

than the kerf from cutting the wedges. So, I just clamp down

on the outside flats of the wedges and apply pressure. This forces

the sides and heel block to butt up tight with each other --

providing the cut angle is correct, of course

Best, Michael

Jun 20 2005, 11:49 AM

Michael,

Too hot to be outside! This should be fun - not punishment.

The other benefit of the Middleton wedges at the neck is the

clearance for rasp work on the heal. I had not seen that before.

Yesterday our RH finally had been hovering around 50 percent

long enough that I felt good about bracing the tops and backs

of the two I am working on. So far, I do not own a dehumidifier.

I think you got along very well with those tuners. As long as

there are no little burrs to catch a cleaning rag, nobody will

ever look at those joints. Nice job.

Steve

Jun 22 2005, 04:18 PM

Good point, Steve, and one I failed to point out. With the extra

width of the 10-string neck, the extra clearance is nice.

Best, Michael

NEXT PAGE / PAGE 1 / PAGE

2 / PAGE 3 / PAGE

4 / PAGE 5 / PAGE 6 / PAGE

7 / PAGE 8

Home / Articles

/ Gallery / Accessories

/ Builders / Composers

/ Guitarists / Movies

/ Sheet Music / Free

PDFs / Recordings / Teachers

/ Radio / Join

/ Contact Us

|